Machining

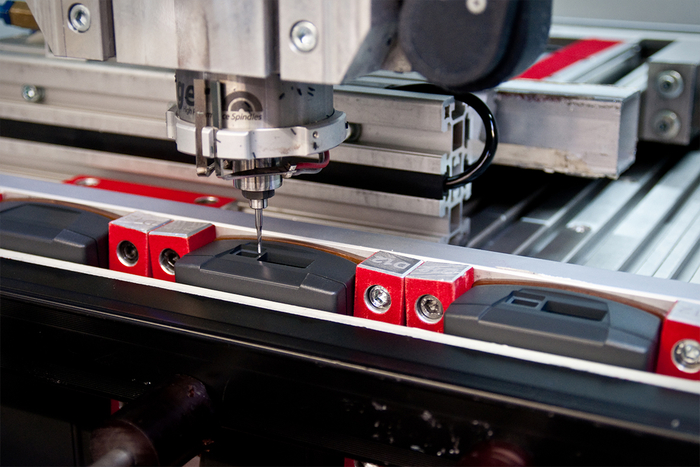

Our enclosures are machine-finished on the premises. At Phoenix Mecano, we have an experienced workforce as well as state-of-the-art machines and systems. A combination that ensures you affordable production runs at a consistently high standard of quality.

At RK Rose+Krieger, we will also undertake the specialist cutting / machining required with regard to Aluminium Profile section / Infill panels and materials / Worktops, etc, along with any special features that may need to be incorporated , such as cut-outs for inspection window apertures, cable tidies, locks etc.

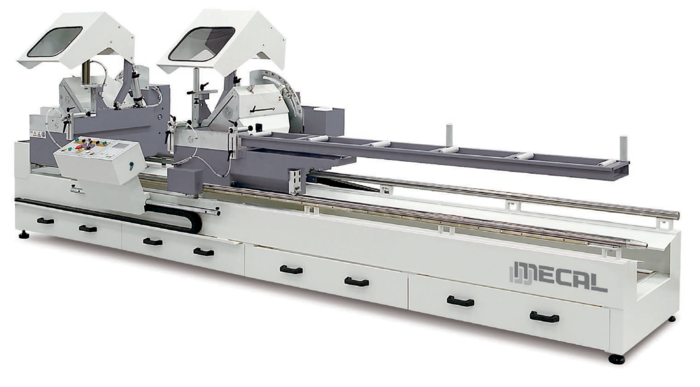

Aluminium Profiles can be cut to =/- 0.1mm tolerance up to 6M long. We also have the availability and capability to supply the Aluminium Profile bent to suit whatever is required for specific applications and projects. Prices can be quoted on application.

Our highly-qualified employees carry out processing for you on modern CNC machines and equipment. This ensures constant and even quality of work. In addition, the overall solution consisting of the enclosure and customer-specific processing results in optimal delivery times while reducing both the risk of rejects and transport costs.

Our range of services includes:

- drilling

- milling

- cutting

- punching

- thread-cutting

Using modern CNC machines and equipment, our highly-qualified and motivated employees saw extruded aluminium profiles in accordance with your specifications. This ensures optimal delivery times and a high level of quality for the products.

We use a special ultrasonic welding method to join the plastic spacer pins to our enclosures.

All our plastic enclosures are equipped with bosses to fasten the mounting plates or PCBs. If you would like an additional fastening method at another position, then we can carry out this requirement by welding in a spacer pin.

When processing plastic enclosures, it is essential that the tools be cooled only using oil-free air. Drilling, cooling and lubricating methods can all lead to stress cracks.

If silicone-based lubricants are used, then a downstream printing process is not possible due to the poor adhesive properties of the lacquer. If cases of doubt, we would be pleased to provide specific information.

When working with our milling machines and planning to make openings, you are advised to apply a general radius of 1.5 mm.

N.B.: Our processing service excludes any such risks.

When punching out plastic parts, crack formation and stress whitening at the corners can never be ruled out. The Phoenix Mecano processing service minimizes any such risk.

The quality of any adhesive connection depends on the materials being glued, the size of the area to be glued and the glue itself.

Make sure to observe the following …

- Only glue parts made of the same materials.

- Aim for a glueing area as large as possible.

- Use suitable glues only. Observe any technical instructions.

- Before serial production, test the adhesive connection under operating conditions such as temperature, load etc.